A crystallizer is a piece of equipment that separates two components. A mixed component liquid phase enters the condenser where the pressure is lowered to cause the more volatile component to vaporize, or the temperature is lowered to cause the less volatile component to fall out of solution. Either method will cause the less volatile component to form crystals and fall out of solution. Due to the highly selective nature of molecule placement during crystallization, this method of separation often produces among the highest purity levels in the crystal phase of any separation method.

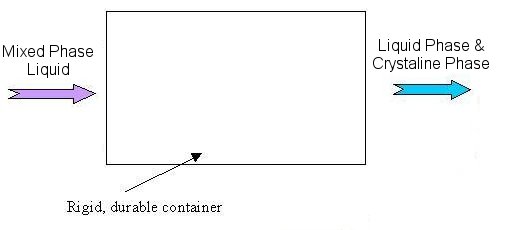

A basic schematic of a crystallizer is shown below:

One mixed component liquid phase feed stream enters the mixer, where the liquid is cooled

or decompressed. Following the growth of the crystaline phase, the mixture is often sent to a

filter or other particulate separation system. The inside wall of the crystalizer will often

have heavy crystal growth due to nucleation properties of the wall. These growths

will need to

be removed and retrieved as well.